Buying wheels can be a little bit overwhelming. At AlloyWheels.com we try our best to make navigating through the mire of PCDs, offsets and centre bore as straightforward as possible, with our wheel search function doing much of the hard work on your behalf. However, it's still sometimes useful to know the basics, so here we go:

The specifications of a wheel will often read as some variation of the below

7.0x17 (Width/Diameter) 5x112 (PCD) et42 (Offset) 73.1 (Centre Bore)

Width/Diameter

The width and diameter are easy enough to visualise and understand. The width (often written as with the distance in inches followed by the letter J) essentially refers to the distance from the front of the wheel to the back of the wheel. With the diameter (also in inches) refers to the distance across the face of the wheel.

Pitch Circle Diameter (PCD)

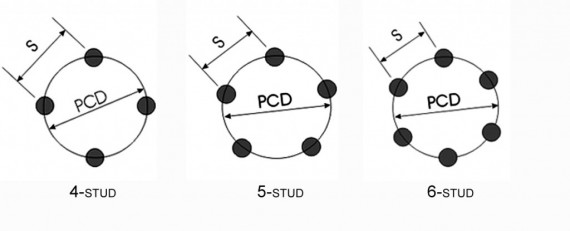

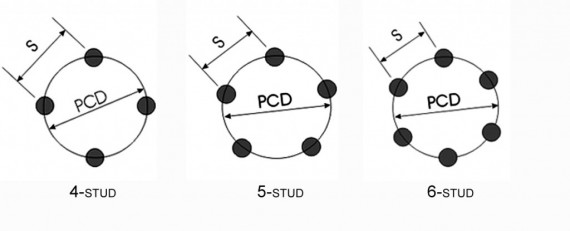

The first part of this (5) is again quite easy to understand as this just refers to the number of holes drilled into the centre of the wheel, this number is most likely be 4,5 or 6. The second part of this measurement is a little bit harder to visualise as it’s a more often than not a theoretical measurement, and it is the diameter of a circle drawn through each of the bolt holes. For clarity, this can be seen in the image below:

If this measurement is unknown, it can understandably be quite difficult to find out, however it can be estimated using the distance (in mm) from the centre of one bolt hole (any bolt hole) to the centre of the one next to it (The ‘S’ measurement shown in the diagram above).

This information can then be input into our PCD calculator (linked below) which can estimate the PCD of the wheel:

PCD Calculator

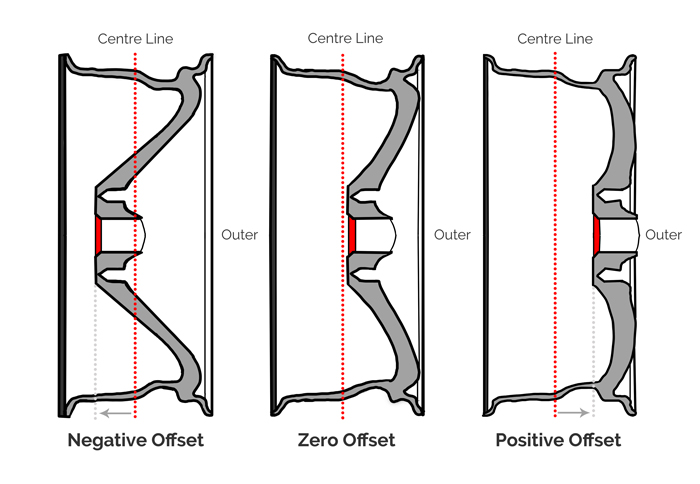

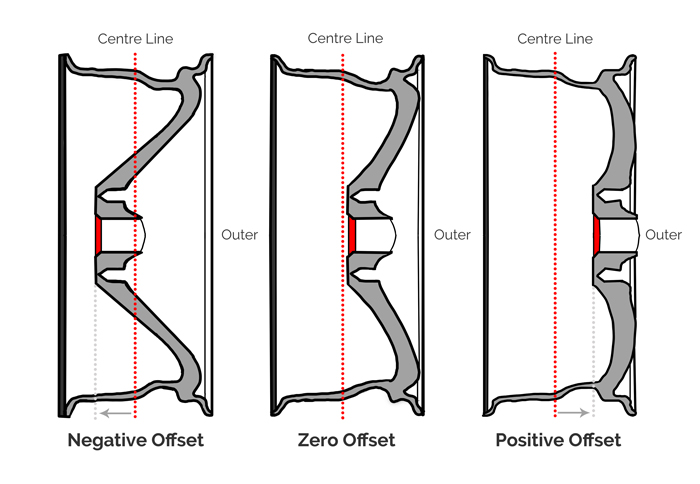

Offset

Offset is another measurement which is quite difficult to visualise and even more difficult to measure. The offset of a wheel is the position of the back face of the wheel (where it meets the hub) in relation to the hypothetical centre point of the wheels width. This can be seen in the diagram below. This measurement is responsible for determining how far in or out of the wheel arch a wheel will sit.

With most alloy wheels, zero and negative offsets are very uncommon. Almost all the wheels we sell will have some degree of positive offset.

All vehicles will allow for a range of suitable offsets in any given wheel diameter, however, if the offset of a wheel is too high or low for a vehicle, the wheel could either protrude beyond the wheel arch or catch on the brake calipers or inside wheel arch.

Again, the wheel search feature on AlloyWheels.com checks for compatible offsets before generating its search results.

Centre Bore

The centre bore of a wheel (the 73.1 measurement in the above example) is quite simply the diameter of the hole in the back on the wheel, where the wheel goes over a vehicle's wheel hub. This can be seen in the diagram below:

In the case of original equipment wheels, both the centre bore of the wheel and the hub diameter of the vehicle will be the same, however, in the case of aftermarket wheels, like the ones found on AlloyWheels.com, this is unlikely be the case. Because there are numerous vehicles that are manufactured with the same PCD, but a different hub diameter, aftermarket wheels tend to have a centre bore larger than that of the vehicle’s wheel hub, and the difference in size is plugged by a product known as a ‘spigot ring’ which essentially reduces the centre bore of the wheel to the size required by the car. These can be seen here:

Spigot rings are very common and if required, are supplied as standard as part of the ‘fitting kit’ included in any wheel package sold by AlloyWheels.com

AlloyWheels.com’s wheel search function uses all these measurements in combination with each other in best ensure the suitability of any wheel package on any given car. While there are in some cases other things that do need to be considered, these are the essential components of a wheels technical specification.

We hope this information has been informative and helpful.

AlloyWheels.com